A scan of the original can be found on archive.org here. Translated to English using Google Translate.

C.I.S. GALATI

CENTRUL DE CALCUL ELECTRONIC

INFORMATICA IN C.S.G.

- DOCUMENTAR -

1988

- Words: mat. Räu Petre

- Graphics and technical editing: mat. Cilinca Florin

- Photos: sing. Sburlan Nicolae

Particular attention must be paid to the stronger increase in labor productivity in all sectors, based on scientific organization of production and work, mechanization, automation, electronicization and robotization of production.

NICOLAE CEAUSESCU

FROM THE PIONEER…

Shortly after the entry into operation of the first processes of manufacturing plant of the famous Romanian steel industry center - the Galati Iron and Steel Plant - the first electronic computers were also installed to control the technological processes.

In 1965, the thick sheet rolling mill no. 1 is equipped with four electronic equipment used to control the lamination boxes and tracking the flow of products.

Thus, the beginnings of the application of informatics to the Galatea steel industry, one of the first beneficiaries of modern computer technology in the country, they materialized through one of its basic branches, known as industrial informatics.

In the autumn of the same year, first-year graduates from the mathematics faculties - computer department - of the Universities of Bucharest and Cluj also appeared in the combined: Amzuica Dan, Noveanu Adrian, Ciobanu Gheorghe, Masgras Vasile and Rusu Cheorghe, some of them having the renowned teacher and tireless supporter as their teacher of the new science of automatic data processing, Grigore Moisil.

Suciu John, who, at that time, worked in the accounting department, recalls with quite a bit of humor the inherent confusion caused then: “I, as an economist, did not realize how mathematicians could be used in a large industrial enterprise. I was not alone. The guru we suspected we economists would continue to deal with additions and subtractions on the horizontal and vertical sides of the documents, accountants and mathematicians will probably make multiplications, divisions and other operations more complicated”.

These mathematicians, together with engineers Ilescu Ilie, Drăgoi Ionel, technicians Vârlan Ranciu, Pintilie Nelu and others, participated, together with French specialists, in the commissioning of the first equipments from the endowment. It was a useful experience, one of the first in our country in the field of using computer technology for pro-technological advances.

Under the guidance of engineer Ovezea Iuliu, the current director of ICPPAM and in collaboration with the engineer Cristesco Mihail, during this period the first computer works were developed - tables for determining the weight of thick laminated and finished sheets. The cards that contained elements of the lamination technologies and the information from the contracts with the beneficiaries of thick sheet metal are also punched.

Shortly after this, another disciple of Professor Moisil, the mathematician Drăgan Petre, was hired by transfer from Hunedoara, and the economists Suciu Ioan and Popa Dan abandoned their careers offered by work in accounting and planning, joining the first group of computer scientists, who are beginning to gravitate around the few existing computers.

The first IT department in C.S.G. took effect on 01.04.1968 and was called the “Calculation Technical Service”.

The act of officialization is done first of all as a result of the growing interests shown by the management of the Galatian steel industry at that time for this new discipline, which is expected to have a strong scope in the economic and social life of the country, through its profound influence on the progress of society.

With the enthusiasm of a trailblazer and with a good experience in the field of typing, Cruceanu Aurelian, who will be called deputy service head of this first IT unit, gathers with the force of conviction and trust a team of 10 people and takes on the work of various trainings and specializations: 5 mathematicians, 2 economists, 1 technician and two operators.

There was, of course, an atmosphere of youthful enthusiasm, warm and full of prospects.

The protagonists of these beginnings remember with nostalgia those times when, next to the hearth fire, lasting friendships based on collaboration and self-help, on the sense of duty towards work and professional responsibility, on unshakable common passions crystallized.

After 20 years of continuous activity in IT, four of them - Amzuică Dan, Suciu Ioan, Moraru Silvia and Lucaciu Felicia - are also attached to the same job, being cadres with positions of responsibility, but also with rich professional experience, each of them having special contributions in promoting this activity.

In the beginning, there was no specific headquarters for the entire team of computer scientists. Some participated with the foreign specialists in the installation of the computers from LTG1 and OLD1, others worked in the Planning service or in the Financial-Accounting service. Only after a few months after the establishment, once the steelworks no. 1, the team of computer scientists finds a headquarters in the current building of the section.

With the integration of the first ideas to approach some fields of activity from C.S.G. along the line of mechanized and automated data processing, the first specialization courses for the staff of the Computing Techniques service will begin, in institutions with more experience in the field, from the country or abroad. At the same time, a permanent renewal of the workforce is taking place, with new staff: Ples Eugenia, Ene Ioan, Robescu Olga, Lucaciu Eugen, Neacsu Ion, Crisan Eugenia, Galben Adriana and others.

In 1969, the engineer Marian Cornel coordinated, as project manager, the commissioning of the computers at OLD1. Accumulating a rich experience in the pioneering stage of IT in Galatea steel industry, effectively participating in the conception and development of some important works of automatic data processing, after a short period of time, he will become the coordinator of the IT activity within the Ministry of Metallurgical Industry, then director of the Center for Calculation of M.I.M., a position he still holds today.

After an appropriate specialization in the field, in 1969 engineer Cristescu Mihail is appointed head of the Computing Techniques service. In the same period, the economist Zaharia Constantin was appointed deputy head of service and made a significant contribution to the introduction and expansion of automatic data processing in the economic field.

Youth, which still characterizes the IT activity at the combine today, could in no way be an obstacle to the enthusiasm and boldness specific to the creative act.

The beginnings in the activity of this collective are closely related to the automatic management of technological processes. The first installed computers generate actions to assimilate their structure and functioning. Mathematicians - computer scientists in the making - in collaboration with electronics specialists and engineers from the Automation - Thermotechnical - Metrology service (ATM) learned computer languages, operation and exploitation techniques, analyzed technological processes and participated in their modeling, thus contributing to the realization and implementation of some basic functions in the field of automation. It was the heroic period, in which time lost its importance, the efforts being subordinated to accumulations and the satisfaction of penetrating the secrets of machines that propelled new activities in the most advanced technical environment at that time.

In parallel with these concerns, some computer scientists actually participate in the development of the first works in the field of typing.

After the first equipment with two sets of typing machines and 14 invoicing-accounting machines of the Soemtron type, the collective of computer scientists begins to organize, mobilize and incorporate the first ideas of mechanized data processing.

Only half a year had passed since its establishment and a group led by Suciu I put into operation the first management application: the valorization of the production handed over to the thick sheet rolling mill no. 1.

The creation of this first application also imposed a need to encode the information. Thus, it was agreed to codify the price conditions through a very simple and useful code.

Over time, the number of brands manufactured exceeded the scope of the 1968 catalog, creating the need to codify the steel brands on plan assortments.

This action became present in 1969 and was successfully resolved by the specialists of the IT unit. The coding of brands manufactured on plan assortments is still used today in C.S.G. on the same structure designed by then.

The production valorization system worked until 1974, when new ideas - corroborated with superior computing equipment - will support the development and modernization of valorization operations and not only them.

In parallel with this application, the mechanized processing of data regarding stock management is carried out, with Cruceanu Aurelian as the main developer.

The application, which worked for several years in a row without being modified, could not be replaced until after the FELIX C-256 computer system appeared, which allowed its development and improvement.

Industrial informatics from C.S.G. it is strongly mobilized after 1969, when eight more process computers were installed. At blast furnaces 1-4, a computer was installed with the main functions of logging and correcting the coke load. A computer is installed at the energy dispatcher of the complex, with the initial functions of collecting and logging data on energy consumption and monitoring the out-of-bounds parameters of energy fluids. At OLD1, two computers are installed that carry out management functions of steel production and casting. One of these will also be used for economic management works.

Along with the foreign specialists, the following also participated in the installation and commissioning of these computers: Mocanu Dumitru, Chindea Stefan, Oprisanu Vasile, Bordei Mihai, Sirbu Chirilă s.a.

The fifth computer is installed in the Slebing section and has the following functions: records of the loading of the deep furnaces and the recording of the parameters at the lamination box for each pass.

Cold strip rolling mill no. 1 was equipped, shortly after that, with a number of three systems that took over the functions of measurement, protocol and regulation of some parameters of the technological process.

The installation, commissioning as well as the development of some functions for these computers are done through a fruitful collaboration between foreign specialists and Romanian engineers, mathematicians and electronics engineers such as: Iliescu Ilie, Catană Costică, Drăgan Petre, Pintilie Nelu, Jurcă loan, Trofin Mihai s.a.

In that early period, the maintenance of the typewriters was provided by Oprisanu Vasile, Vârlan Ranciu and Lucaciu Eugen, and the office machines from C.S.G. go under the direct assistance and maintenance of a band led by Serban Cornel.

Considering the diversity of types of electronic computers with which the sections and sectors of the combine were equipped, the need to improve the maintenance activity of these equipments appeared. In 1969, the management of the combine took the measure of centralizing the activity of maintenance of computing equipment. The staff from the departments equipped with electronic computers, who participated in their installation and commissioning (some of them specializing in the supplying companies), constituted a separate compartment of the ATM service.

This department will later form the core of the Computing Office for process computers which, together with a design group, still functions today within the Computing Center of C.I.S. Galatians.

The available capacities of the process computers have also created possibilities for the realization of some management applications. Initially they were oriented towards production management.

Since 1969, the beneficiaries, steel brands, technological samples and contractual positions have been codified.

After the codification of the main information, the collection templates were designed on punched cards and the contract file was built, which was manually updated every day by Suciu Ioan and loaded into the computer by Noveanu Adrian. Based on the existing data in the contract file, Cristescu Mihail and Amzuică Dan designed and created the LAMI program that elaborates the lamination and adjustment technological sheets at LTG1. At that time, the work aroused great interest among users and specialists through the efficiency with which it exercises its implemented functions. It replaced a large volume of manual work. This fact is prominently highlighted by an incident when, in the event of a computer failure, it was necessary to hire a workforce of 15 people per day to manually perform the operations that the program executes.

The program worked, with some small modifications, until the appearance of the large FELIX series computers.

The existence of the information from the contracts on the Siemens system generated at a given moment the idea of carrying out the first work of tracking the contractual discipline through the automatic operation of the shipping notices.

The application did not reach today’s precision and operational performance, but the first steps in this direction have been taken. The first steps were also taken in those years in many other fields. Other important applications were developed on the same system, such as:

-

processing data from the bill of lading at the steel mills,

-

scheduling the production phases of the cold strip rolling mill,

-

processing teaching notes,

-

calculation of remuneration,

made by Noveanu Adrian, Drăgan Petre and Ples Eugenia.

The year 1971 coincides with the hiring of new graduates of specialized faculties in the country: Borza Ion, Giosanu Mihai, Darie Constantin, Maxim (Mizileanu) Minodora and Felman (Giosanu) Eugenia. With the exception of Borza lon, who in 1979 transferred to Deva, the others are still attached to their old workplace, where they developed and improved professionally, becoming responsible staff in the Computing Center.

The pioneering stage ends towards the end of 1973, with the transformation of the Computing Techniques service into the Computing Center and the provision of the first system from the FELIX family.

…AT THE AGE OF MATURITY…

Benefiting primarily from party decisions regarding the development of IT in our country, C.S. Galati was equipped in 1973 with the first FELIX C-256 computer, which had 128 kb of operative memory and 28 Mb of external memory upon installation.

The appearance of the new computer system gave a special impetus to the collectives of designers who direct all their efforts towards loading it with useful applications.

The first major action is the assimilation of the most common programming language on this computer: the COBOL language. Its assimilation is done almost on the fly, at the same time as the design and construction activities.

In February 1974, the first application on this system came into operation: LIVINC - record of delivery and collection of C.S.G. products, made by Suciu loan.

Gradually, all other applications made on the SIEMENS-303 computer are redesigned and implemented on the FELIX system, which offers wider exploitation and development possibilities.

New specialists appear on the benches of specialized faculties in the country who integrate quickly and devote themselves to the passionate work of computer scientist.

The work of the analyst-programmer is developed and shaped by the increasingly useful services of the personnel with secondary education.

The battle for the new was in full swing. No effort was spared in this fight.

Imagine some young people who got excited with each more efficient program execution, who could not contain their joy of their own achievements, who vibrated and got excited with each new implementation, who often sacrificed their free time with their struggles and searches for new, more efficient solutions and you will discover the characteristic atmosphere of this collective of computer scientists.

Imagine the satisfaction with which they shared with each other new secrets discovered in the use of the tool of the twentieth century, ideas and courses of action in approaching and exploiting it, and you will have in front of you the richness of the spirit of collaboration of these young people.

Without a doubt, the basic activity becomes the analysis, design and implementation of automatic data processing applications. The need to replace the routine work, unitary, fast and precise processing of the data from the compartments and sections of the combine was increasingly acute.

Starting with the year 1974, the activities related to the management of the base production gained special importance. In the organizational structure of the Computing Center, new orientations are made, creating design teams for the main activities of the complex. A new headquarters is established for all designers: the 5th floor of the tower annex. In collaboration with a team from I.C.I., coordinated by Tudorache Marin, the records of contracts are designed and implemented on the new system. The first ideas of tracking the metal in the flow at the finishing sections appear and, for this purpose, three teams are formed that bravely attack the proposed problems. Engineer Tanăsescu Ionel supports the entire action by establishing relationships with users and formulating problems. Three large applications are analyzed, designed, programmed and realized in this way that process the documents of interphase movements and production scheduling on the section flow: lamination and adjustment programs, production reports, handover notes and shipping notices.

The “contractual discipline”, carried out in those years, was oriented towards relationships and products, because in order to edit some situations of a certain section, it was necessary to run specific procedures for all the products of that section. Users were dissatisfied because the data were not operative, there were delays in approvals of 10-15 days, especially in the periods at the beginning of the month.

The commercial requirements of the combine regarding the pace and efficiency in the circulation of information were becoming more and more pressing.

In the fall of 1975, the idea appeared that would mean a qualitative leap and proof of maturity in the creative thinking of the design team: “In order to have a contractual discipline useful to all the decision-makers in the combine, we must first perform the basic production invoicing on an automatic system; this will discipline both us at the Computing Center regarding the operative data processing, as well as the users in the rhythmic transmission of shipping notices, because the invoice, according to its legal status, had to be deposited in the bank daily, with a delay of maximum 24 hours after the wagon leaves the compound”.

It was said then that automatic invoicing is not possible, that it is a utopia. There was nothing similar in the country, and the attempts undertaken in isolation in a few economic units often hit the insurmountable barricades of normative acts not yet adapted to the requirements of automatic data processing. But… in our own actions sometimes situations arise that can mark turning points when we arm ourselves with skill and courage.

And the action begins. At that moment, there were already, in a beginning form, some bases on which the whole action will be supported. The team from I.C.I. has the merit of conception and realization of the initial structure of the database, elaborating the first maintenance programs which are then taken over and developed by Borza Ioan.

Attached to these data are files containing information about shipping notices and delivery notes, which we still find today under the name then given of “common files”.

What was missing? The possibility of updating production and delivery prices, with direct implications on invoicing and production valorization.

In solving this problem, a fresh analyst, Emil Hendoreanu, is engaged, who firmly triggers the action that will result, nothing more, nothing less than a unique module for calculating prices. What a unique module means is easy to understand, but what was hiding behind this subprogram?

For those who do not know what a price catalogue for steel products means, we put their imagination to the test and invite them to imagine a methodological document of over 100 pages, all full of tables of various geometric configurations, made up on various criteria, which contain prices and numerous indications of their application. Add to these various contractual clauses, various normative acts that regulated the calculation methodology and you will have the dimension of what a price catalogue means.

The price calculation subprogram is itself a “mammoth” program, which in turn calls about 18 other subprograms written in the FORTRAN language. This module was created and put into operation at the end of 1975. It is efficient, it includes all the legal conditions for the calculation and application of prices and opens wide perspectives regarding the invoicing of goods production, the valorization of the delivered production, as well as a contractual discipline with real chances of gaining the trust of users.

Another first important event follows: the invoicing of the basic production. It takes place on October 22, 1976, when, with emotions from both the producers and the users, after three weeks of postponement of the implementation due to the last-minute observations of the bank inspector, the first invoices with the corresponding coupons appear. The joy was immense, it cannot be described in words.

The importance of the event appears even more significant today if we were to highlight some facts related to it.

The first refers to the minute concluded between the Computing Center and the beneficiaries of the work. It stipulated that in the event of a computer failure, manual invoicing should be used throughout the entire period of the failure.

Until now, although there have been periods of this, for 12 years there has never been a return to the manual preparation of invoices, as this – with the passage of time – became almost impossible. When it was necessary, the computers of other units in Galati or Braila were used, the maintenance team was mobilized to keep the computers in working order and for their quick troubleshooting, but the automatic invoicing was never given up.

The second fact refers to an approximate estimate established recently, regarding the volume of manual work required for invoicing the basic production of the combine. A brief analysis in this regard highlights the fact that the manual invoicing of the entire production in a single day would require at least 100 people. Today, the billing office has only 15 employees.

As predicted, basic production invoicing imposed a discipline on the rhythmicity of arrival of delivery documents for automatic processing.

On these bases, the analysis, design and realization, in a unitary system, of the processing of data from shipping notices and waybills for all departments began.

With regard to the exploitation of the database, a program was created that created the premises for the development of many new applications, among which we mention one of the most important regarding the tracking of the realization of the delivery schedule, the circulation and the lean stock.

A qualitative leap in the field of data preparation – and not only that – was recorded immediately after the installation and commissioning, in 1977, of the Hewlett-Packard 2000 minicomputer. The new system, which allows the conversational working mode, makes it possible to pass the entire activity of collecting data from punched cards to magnetic media, clearly increasing work productivity and the quality of information. The data collection systems on magnetic media – using various types of terminals and HP 2000 and FELIX C computers – created by Darie Constantin, Ciubotaru Alexandru, Irina Mihai and Chelemen Cornel enjoyed a well-deserved success, being taken over by other units of computer science in the country.

In 1979, the first remote processing applications appeared, thus providing the management with operative information regarding the daily and even hourly situation of the realization of the plan, technological stops, energy consumption and the production of cast iron, steel and laminates.

In the same year, the idea of integral tracking of the metal on the flow appears in a new, unified concept, based partly on remote processing through the HP-2000 system – for the production of steel and semi-finished products – and the other part on the processing of production documents from the finishing mills. Work was done for this, the system was created that went into operation for a period of time, but the results were not up to expectations, the idea being taken up later.

At the beginning of 1980, two more computer systems of the FELIX C-512 type came into operation, intended mainly for the management of basic production.

If until 1981 the design activity was fought under the motto “everything for the users”, the time had come for the computer scientist’s own work to be perfected. programming activity: punched cards were abandoned and programs were collected and corrected directly on the system terminals. In a short time, a substantial increase in the productivity of programming and testing work was registered.

In this period, production invoicing also extends to the auxiliary production of the combine, and the utilization of the delivered production is developed for all the finishing sections and all the basic products of C.S.G..

In 1982, the STRATEGE system was installed on the FELIX computer, which allowed the development of new teleprocessing applications, the data being updated directly by the users. Contributing substantially to the promotion of applications on the STRATEGE system, mathematicians Ciubotaru Alexandru, Darie Constantin and Irina Mihai are among the first to assimilate and understand the secrets of this product. In this way, scheduling, monitoring of manufacturing, stocks, monitoring of the delivery schedule and contractual discipline are carried out.

A special mention must be given to a new important moment in the development of informatics in the field of basic production management, namely the realization, starting with the year 1980, of flexible systems for selecting and classifying information according to dozens of criteria and their variants, allowing fast and dynamic updates. These systems provide the necessary information for the daily and weekly analyzes of the C.S.G. management with the production sections, for directing the production and the rhythmic dispatch of the goods produced.

In parallel with the design activity for the management of the basic production, an intense activity is carried out in the line of design and realization of economic management IT systems. The specificity of the works in this field is oriented towards the development of large-scale IT systems, including laborious activities such as personnel, remuneration, financial-accounting, supply, mechanical-energetic and the manufacture of spare parts.

The GESTOC application is redesigned and developed, reaching high performance levels.

The PERSORET application is strongly developed, reaching today to have an integrated system of personnel records, calculation of remuneration and records of deductions.

The high performance of the FELIX C-512 systems allowed the development of new management applications as well as the addition of new functions and the improvement of the operating parameters of the existing applications.

Under the direct coordination of some experienced designers (Munteanu Stefan, Mizileanu Minodora, Pavel Nicolae, Gorie Matei, Giosanu Eugenia, Turtă Ioan and Merloi Pavel) new applications appear one after another that replace a large volume of manual data processing.

In the field of spare parts manufacturing, the following is carried out:

-

management of technical data of machines, components and structures;

-

management of spare parts manufacturing technologies;

-

the elaboration of the execution documentation of the spare parts.

In the field of equipment repairs and maintenance:

-

planning and follow-up of AMC checks;

-

planning and monitoring current capital repairs and technical overhauls;

-

management and follow-up of electric motor repairs;

-

evidence of the use of the time fund of the machines.

In the field of supply:

-

substantiating the need to supply;

-

operative follow-up of technical-material supply;

In the financial-accounting field:

-

record of material values;

-

record of fixed assets;

-

accounting C.S.G.

In 1981, the analyst Munteanu Stefan and a group of young enthusiasts started with courage and passion the construction of an IT system for managing the financial-accounting activity – CONTAB. Through it, the automatic accounting of all the data processed by other applications, which are the subject of registration in the accounting records: record of fixed funds, management of material values, calculation of remunerations, records of retentions and production invoicing is carried out. The system – which allows accounting on three organizational levels (unit, plant, section) – has been adopted by several metallurgical enterprises and can be applied in any economic unit.

The work, carried out in stages between 1981 and 1985, was approved by the Ministry of Finance, for generalization.

The year 1985 coincides with the establishment of a new headquarters for the Computing Center, located next to the main entrance to the Galatea iron and steel fortress.

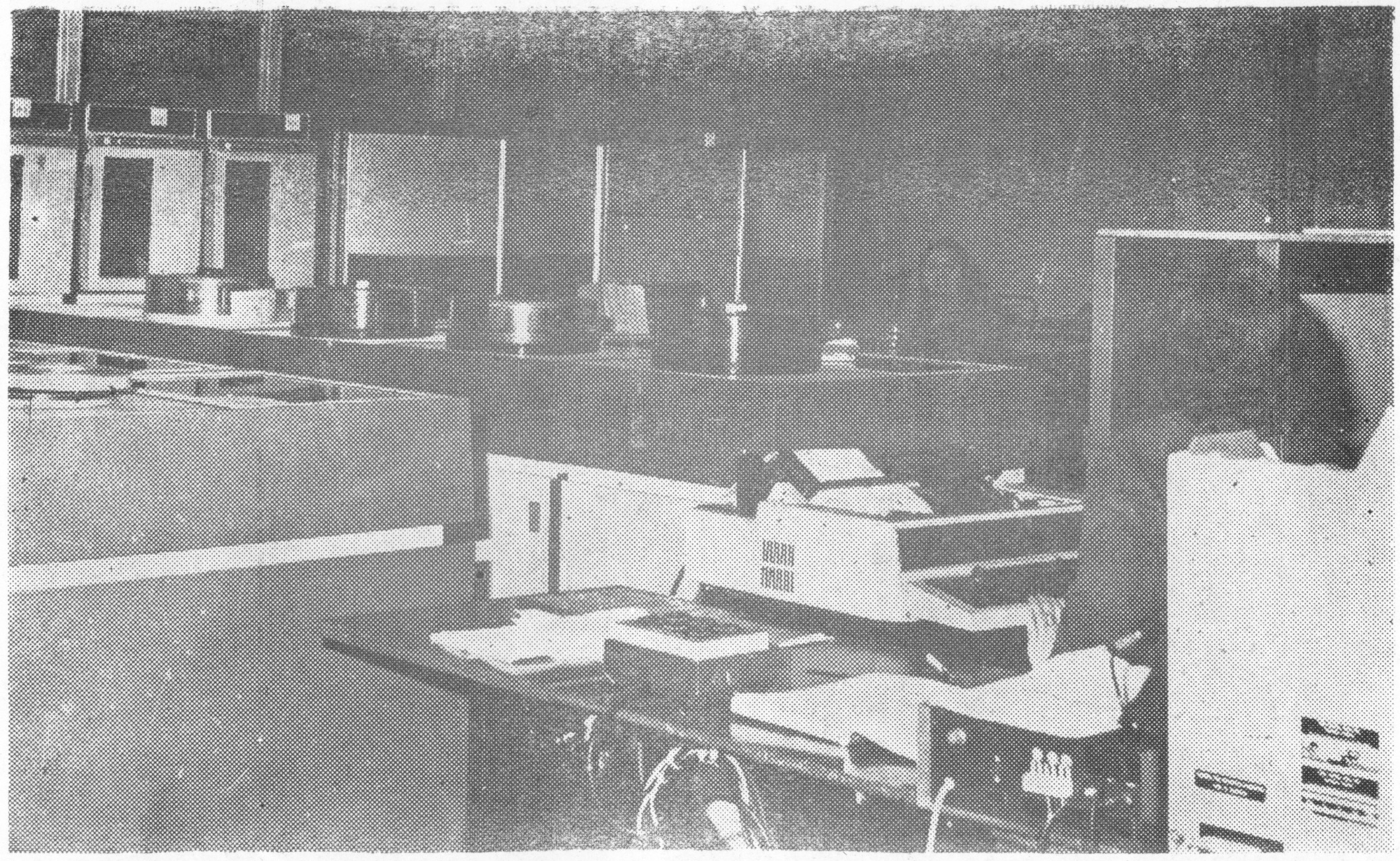

Next to the “old” computer FELIX C-256, transferred to this building, a powerful computer system from the same family, FELIX C-1024, was installed in 1985, reserved entirely for the exploitation of management applications. This system has 1 MB operative memory, 300 MB external memory with direct access, 16 lines of asynchronous communication and 4 lines of synchronous communication.

The second and most important qualitative leap in the programming activity was recorded in 1986, when the ARIEL product was implemented. Using the DAF-2020 terminals and the possibilities of this product, the execution and testing of programs were practically brought to the programmer’s desk. In this way, a substantial increase in the productivity of design work is recorded, as well as an economy of technological materials. Indisputable merits in the introduction of this ultramodern work “tool” go to the computer scientists Tudorică Remus and Irina Mihai.

In parallel with the IT activity, experienced analysts from the Computing Center – coordinated by Stănescu Gheorghe and later by Popa Tudorel – participated in numerous rows, together with other specialists from the complex, in carrying out work to simplify and rationalize the information flow, to reduce the forms to what is strictly necessary. By simplifying the records within the production sections and functional compartments, around 30% of the used forms were eliminated until 1985.

With regard to the automation of the management of technological processes, the complex was intensively equipped with electronic equipment of various types. In recent years, this line of action has gained a special scope, being among the leading activities within the programs for the modernization of production processes. Numerous technological process management systems have been developed for almost all the important sections and sectors of C.S.G.

Having a pronounced specific character, right from the beginning the activity of designing and developing software for process computers is separated from all other IT activities. It acts in a close interdependence with the particularities of the electronic equipment it comes into contact with, with the specifics of the technological process where it is implemented and with the nature of the problem to be solved. For this reason, a varied range of specific works resulted, which required groupings in work teams by action areas.

In 1975, the plant was equipped with the first PDP-8E type minicomputer, installed in the galvanizing workshop.

At furnace no. 5, in 1978, a mini-computer was put into operation with which the order and correction of the furnace loading is carried out, and an electronic equipment installed recently, realizes the supervision of the main parameters of the furnace.

Furnace no. 6, the largest in the complex and in the country, was equipped with a mini-computer that, through the functions implemented, realizes the programming, command and correction of the loading of the furnace.

The systems from furnaces 5 and 6 are among the most complex that the combine has, the last one being representative of what can be obtained through automatic driving.

The economic effects of the computer management systems of the cast iron production process are materialized by reducing coke consumption on average by 3 kg/t cast iron and increasing productivity by 1%.

Mathematician Paraschiv Petre stands out for his rich experience in this sector of activity and for his special contributions.

Along with the modernization of the electrical actuation installations at the hot strip rolling mill, two mini-computers were installed and put into operation with the help of which the technological process is carried out automatically.

After 1984, an important change took place regarding the provision of equipment for managing technological processes, moving to the design and implementation of Romanian-made hard support systems: minicomputers CORAL, INDEPENDENT and microcomputers SPOT83, ECAROM 881.

In the Slebing section, the ECAROM 881 equipment was installed, which optimizes the thermal regime of two deep furnaces, as the first stage of the realization of an automatic control system for ingot heating.

At LTG1, the CORAL 4030 mini computer, installed in 1984 together with two ECAROM 881 equipment, manages the heating of the slabs in the propulsion furnaces.

At LTS, the ECAROM 881 microcomputer controls a pipe weighing installation.

At the energy dispatch of the steel platform, with the help of a system made up of a CORAL 4021 minicomputer and two SPOT83 microcomputers, the management of gas and electricity production and distribution activities is carried out.

At the laboratories, a number of 5 PDP-11 minicomputers ensure the control of the equipment for spectral analysis of steel and cast iron samples.

In addition to these systems, the Computing Office also has three microcomputers for program development.

An important moment in the development of industrial informatics in C.S.G. It was the implementation, in the fall of 1985, of the first Romanian operating system for process computers - ROS8-P.

This product - thought and created entirely by several specialists led by the head of the Computing Office, engineer Preda Mihai - is a real-time, multitasking, productive and diverse operating system, at the user’s fingertips, offering independence from the equipment on which uses. All these attributes determined a well-deserved recognition of the product on a national level, being registered in the National Library of Programs and implemented in a short time on 8 computers from C.S.G. and two from Rimnicu Vilcea.

Some communication programs between mini-micro and micro-micro computers are also on the same line of basic software development.

Within the Computing Office, the maintenance and troubleshooting activity has been required ever since the installation of the first electronic computers in the complex. The great diversity of equipment available has made this activity increasingly complex and laborious.

It is not at all easy to keep 8 production management computers, 39 process computers, over 120 terminals, 16 air conditioning systems, dozens of invoicing-accounting machines and over 1500 office computers in working order.

The exploitation activity develops from the beginning in parallel with the design activity, directly depending on it.

If the first computing systems were limited in terms of processing capacity and the relatively low number of applications in operation, with the appearance of the systems from the FELIX family, the exploitation activity takes on a special scope.

At the same time, the development of numerous applications requires a rational organization of this activity, aimed primarily at the performance of good quality services.

In the first years of operation of the FELIX systems, the indices of extensive and intensive use reached only 70%. In recent years, these indices have increased substantially, with some equipment recording exceptional performance by achieving an extensive use index of 99% and an intensive use index of 310%. Among those who constantly took care to achieve these performances, the head of section Giosanu Mihai and the engineer Schlahetka Iosif stand out in particular.

The data collection amounts to about 3,000,000 transactions per month, of which 2,000,000 are sent to the computer directly by users through teleprocessing systems.

Exploitation activity currently involves a permanent circulation and processing of several tens of millions of characters per day, of which approximately 6000 pages are edited. This means, in a suggestive estimation, that the characters of twenty volumes of about 300 pages each are printed on the computer every day.

Since 1973, a group of system engineers has been working in the operation of computer systems. Their interventions on operating systems or program packages have always been oriented towards the development of computer exploitation possibilities. The adaptations for working in “block mode” with the STRATEGE system, the development of utilities to increase operating performance and safety in operation, the introduction of the ARIEL system in order to facilitate the programming activity are just some of the results of their activity.

In recent years, the Computing Center has registered prestigious achievements in the field of technical creation, an activity carried out by some of the most passionate computer scientists.

In this direction, it is appropriate to mention the first invention registered as such and made by a team led by Nicolae Pecheanu and Dan Praisler: “automatic positioning of rolls of hot rolled tape in front of the mandrels of the LBR1 unwinder”.

Cristescu Mihail, Minzu Viorel, Icriverzi Nicu and Macarie Corel created a mathematical model for optimizing the heating of slabs in propulsion furnaces.

Ion Ilie and Pecheanu Nicolae made a system for measuring the sheet width at LTG1, the latter also made a multiplexer of analogue inputs from the process.

Hodorogea Dorinel signs the realization of an asynchronous communication multiplexer for FELIX type systems. The same author develops some functions of the DAF-2010 terminal to expand the possibilities of working with the printer.

Costoiu Alexandru realizes with his own forces a terminal switch and connections between computers, as well as a line adapter for asynchronous communication at a distance.

Baboi Dobre built a communication interface between the HP terminal and the SCAMP printer.

A mini telephone switchboard, very useful for the development of the possibilities of quick conversation between the computer room and the locations of the terminals, was made by Trofin Mihai.

The young man Lucaciu Eugen recently signed off on the creation of a device for loading cassettes and gluing scraped tapes.

All these achievements, as well as many others, have contributed substantially to the development and improvement of activities based on the use of modern data processing techniques, to the increase of work productivity.

It is worth noting that the introduction and development of informatics in the compound was based on the continuous support and the encouraging spirit of the users, who understood the role and efficiency of automatic data processing.

The applications made in the combined have effectively and decisively contributed in many cases to the improvement of the management system of production and economic activities.

Computer science has proven not to be a luxury, but a necessity. This is today a unanimously recognized opinion. But one thing must be brought to light: the efficiency of the computer does not result from the automation of old procedures, but from solving the problems of the decision-making system.

…AND IN THE PERSPECTIVE OF THE 10 MILLION

The results obtained up to now, both in the line of equipping with computer technology, as well as in the line of introducing computer systems, fully demonstrate the correctness of the measures taken by the party and state leadership in this field of activity.

Following the working visit of the general secretary of the P.C.R., Comrade Nicolae Ceausescu, in September 1987 to the combine, a series of general directions of action resulted in the qualitative and quantitative development of production. Among these, the one related to the achievement in the following years of a production of 10 million tons of steel annually has direct implications on the automation and modernization of production, opening new horizons for the development of informatics in C.S.G.

In perspective, the IT activity in the complex is oriented in two main directions:

-

expanding the use of automatic data processing for production management and technical-economic activities;

-

the realization of new management systems of technological processes as well as the improvement of existing ones.

In the field of production management, the completion and phased commissioning of the llth stage of the investment “Computing centre and automatic data processing system at the Galati Siderurgic Plant” is foreseen. The main objective of this stage is the creation of an oriented teleworking network on the two existing processing centres (ULP annex and CCE headquarters), where eight more CORAL minicomputers and one FELIX 5000 computer are to be installed.

In order to create the remote processing network, the installation of 129 screen terminals and 92 printing terminals is foreseen, their “density” being higher for the management activity of steel and laminate production. The main areas of activity in which remote processing will be expanded are:

-

management of basic production in the steel-making area – semi-finished rolling mills – finishing rolling mills;

-

managing the production of spare parts;

-

technical-material supply and tracking the movement of material values;

-

tracking the movement of CFR wagons.

At the design workshop no. 2, a long-term program was designed for the design and implementation of the teleprocessing production management system.

In the field of the management of technological processes, the perspective of the humiliation of electronic computers until 1990 is defined by the “Program for the organization and modernization of production processes in C.S. Galati”. According to this program, computers will be put into operation for the control and command of the technological processes on the entire production flow, the Computing Center being directly involved in the realization of 20 works from this program, which will have the following main effects:

-

reduction of consumption of raw materials, materials, energy and fuel;

-

increasing the productivity of machines and installations;

-

improving the quality of the products.

The endowment in the spirit of this program provides for the commissioning of another 16 minicomputers, 20 process couplers and 70 terminals.

In the main production sections, management systems of the technological processes will be created, as follows:

-

at furnace no. 4, a management system with functions similar to those existing at furnaces no. 5 and 6;

-

at LTG 1, on the system installed in 1985, the programming and operational monitoring of the production as well as the management of the rolling process will be switched on;

-

at LSF, the system for optimizing the debiting of semi-finished products;

-

at LBC, the systems for directed cooling of the belt and optimization of the heating of the slabs in propulsion furnaces;

-

within the LBR2 section, the automation systems from tandem, dressing, quarto box and transverse cutting line no. 8;

-

at TC1, the operational management system of the moulding machine no. 1;

-

the current energy dispatch system will be expanded using Romanian equipment.

The own program of research and introduction of technical progress contains topics whose main objective is to increase work productivity in the specific activities of the Computing Center.

Also included in this program are experiments and implementation of new products, equipment and techniques, the application of which aims to prepare the conditions for the further developments of informatics in the CSG.

There are concerns for the improvement of the human-computer dialogue and the creation of expert systems. Started as individual research topics, they generally refer to the processing of symbolic information such as conceptions, knowledge and relationships. They aim at the development of systems through which computing techniques are involved in solving practical problems that have characteristics associated with human intelligence: learning, judgment and problem solving. The development of expert systems for the complex problems of steel specialists represents an ideal for the passionate researcher in the field of artificial intelligence, Rău Petre.

There are also concerns in the field of shape recognition and image processing, recently signed by the mathematician Macarie Corel, for the creation of automatic measuring devices, on the flow, of the dimensions of laminated products.

We cannot end this foray through the achievements and perspectives of the IT activity except by recalling that the Computing Center of C.S.G. it means a collective of analysts, programmers, electronics and operators, it means a collective of 250 working people: mathematicians, economists, engineers, technicians, foremen and highly qualified workers, it means a large collective of intelligence and passion.

But it doesn’t mean only that. Computer science is not their only passion. In several rows, the workers from this collective have valued and creatively developed their cultural, sports, etc. potential.

-

During the years 1976 - 1978, the Computing Center asserted itself in its cultural activity by presenting a highly popular artistic brigade at the “Cintarea României” National Festival. In 1978, this brigade, whose text was signed by the late colleague sub-engineer Eugen Lucaciu, won well-deserved applause even in the final stage of the festival. In the limited framework, the suggestively titled “Bitigada” program, composed by the engineer Mihai Preda, also enjoyed great success.

-

For a short period of time he well-known light music soloist Marcela Alexandru worked as an operator at the Computing Center. Due to his talent, in 1977 he participated in the “Steava fără nume” competition, became a soloist of the “N. Leonard” Musical Theatre in Galati and later joined the famous collective of the Bucharest theatre “C. Tănase”.

-

A special cultural activity is carried out by the operator Elena Popa who, starting from 1980, participates in numerous folklore festivals as a dancer and singer of popular music. In the 1981 building of the “Cintarea României” National Festival, Elena Popa contributes to occupying the first place by the “Bala Ofelului” ensemble. Then followed other leading places obtained at various competition festivals: “Costesti – 1982”, “Cintă de rasună lunca” s.a.

-

The famous Bärbätes choir of the Galatian steelworkers, laureate in several editions of the “Singing of Romania” National Festival, has benefited over time from several talented representatives from the ranks of computer scientists. The most assiduous participant among the members of the Computing Center was – and is currently – analyst programmer-assistant Ioan Turcu.

-

In 1981, the first internal chess championship was held, which enjoyed a large participation. The title of champion of the competition was obtained by the director of the Computing Center himself, engineer Mihail Cristescu, a great enthusiast and animator of this sport of the mind.

In the following years, the chess team, led by analysts Emil Hendoreanu and Petre Rău, achieved several successes by occupying leading places in the competition with the other teams of the Galatian steelworkers or of the municipality.

The two participated in the same period in the individual contests within the republican men’s chess championship, obtaining great classifications and qualifying in several rows in the quarter-finals of the competition.

-

After graduating from the Faculty of Mathematics, in 1980 the international master and multiple national chess champion Dana Nutu worked for a short period of time as a programmer at the Computing Center of C.S.G. The famous chess player then made contact for the first time with the “force” of an electronic computer, which he challenged to a duel… chess. Of course, the artificial intelligence lost the game, although – by his own admission – human intelligence was not lacking either then of emotions.

-

The men’s volleyball team achieved several successes in sports competitions with other similar teams in the combined. A great animator, during the glory period of the team, was the engineer Costică Catană.

-

After a rich activity, carried out between 1980 and 1985 in numerous cups and republican correspondence chess championships, Petre Rău was co-opted in the county correspondence chess team, contributing to its success which, in 1986, was realized by qualifying in the final phase of the national competition.

-

The table tennis team has taken leading positions several times at various internal or municipal competitions, held during the years 1980-1983. The best individual results are recorded by analyst Ioan Circu.

-

Between 1978 and 1984, the Computing Center also had a football team that recorded some “small successes” in sports competitions with other similar teams in the complex.

-

The engineer Mihai Preda is a great caricature enthusiast. On the occasion of some symposia, his artistic works enjoy great success, most of them having no pronounced character specific to the computer science activity. Another caricature enthusiast is the mathematician Pavel Merloi.

-

In 1985, the mathematician Petre Rău created a computer program for solving chess problems, which he presented in the final phase of the republican programming contest initiated by the magazine “Stiintă si tehnîcă” in collaboration with ICSIT-TCI. Shortly after, the same author creates the SP-64 program for the game of chess, a program that is widely appreciated. In March 1986, at the scientific session with the theme “A decade of electronic chess in our country”, held in Herculane immediately after the end of the first national festival of computer chess, SP-64 was declared the second original program made in the country in the line of computerization of this mind game, the great and eternal “guinea pig” of artificial intelligence.

-

Alexandru Popa, locksmith at the Computing Center, is also a well-known and passionate pigeon fancier. His pigeons – messengers of the peaceful flight – are instigators of leading places in numerous national competitions, in which the launch is made from thousands of kilometres, in Czech, Polish towns, etc. Among other achievements, the pigeon fancier holds a unique regional record: he has the largest number of classified pigeons.

The anniversary of the two decades of the existence of informatics in C.S.G. takes place under the sign of the revolutionary pretences determined by the decisions of the XIII Congress of the Romanian Communist Party, of the National Conference, which offer new perspectives for the development and modernization of the steel industry, with deep implications for the full affirmation of creative forces and capacities, requested in the direction of automation and cybernetization of production processes.

The actions and concerns of the Computing Center are today oriented towards the extensive process of expansion and modernization of the complex, pulsating alongside the thoughts and deeds of the Galatian steelworkers, for the fulfilment of the great tasks outlined by the party and state leadership.